Common faults of bending machine and solving measures

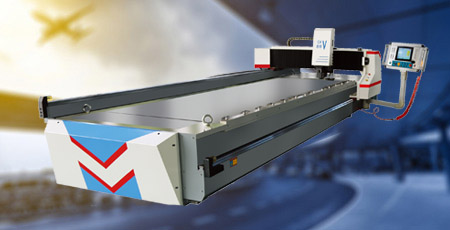

Bending machine is a machine capable of bending of thin plate, the structure mainly comprises a bracket, table and the clamping plate, the worktable is arranged on the supporting table, which comprises a base and a pressing plate, a hinge is connected with the clamping plate through the base by a shell, a coil and a cover plate, the hollow coil in a shell sag, top cover.

What are the common faults of the bending machine? How should we deal with these failures? It's a headache and a tough question, so let's look at it today, find the best answer, and provide some valuable knowledge for the readers.

Fault one: the CNC system is abnormal when the power is on

This fault is usually caused by software, misoperation or frequent abnormal shutdown in the operation may lead to file loss, so that the software can not run properly. You can judge by the prompt of the system, and then decide whether to reinstall the software.

Fault two: slider movement fault

The slider movement of the machine tool can be divided into four processes, which are zero return, fast drive, working stroke and slider return.

Y axis movement: don't change the slider is measured according to the electric principle diagram, in order to determine the hydraulic system failure or malfunction of the electrical system. If the servo valve gets power normal, that is the hydraulic system failure, otherwise it is the electrical system fault.

Fast forward: no slider slider is fast by inferior vena oil return, rely on the slider weight in the upper chamber to form a negative pressure suction and produce, can also according to the situation of electric servo valve to judge the fault of the hydraulic system fault or electrical system, and then solve.

No entry for slide block: same method.

Regular maintenance of bending machine, divided into several aspects: appearance maintenance, slider maintenance, hydraulic lubrication, maintenance, electrical maintenance

(1) the appearance of machine maintenance: wipe to wipe clean, no dirt and stains; parts should be installed if there are defects.

(2) maintenance: check and adjust the slider on the slider on the table and parallel, scrape the slider and remove the guide burr, each clearance should be adjusted properly; check and adjust the direct control of the balance valve, wiping guide, screw rod, and the sliding surface, such as wear parts should be replaced.

(3) hydraulic lubrication maintenance: pump, cylinder, piston, filter, reversing valve cleaning and inspection, burr should be removed, wear should be replaced; oil quality, oil volume to be checked, the oil circuit should be unimpeded.

(4) electrical maintenance: motor and electrical box cleaning and cleaning, grease timely supplement or replacement; check whether the fastening device loose, but also to the line and control system maintenance.

- PRE:No

- NEXT:No